Screw Gauge, Metric, Size, Clearance Holes, Pilot Holes & Wall Plugs

I’ve explained this screw data in an easy to understand table because I find manufacturers recommendations are often vague and general, I mean; why not be specific? I understand there’s a ‘range’ but why not give us the ‘ideal’ measurement, because mostly we have a choice?

The table below shows you:

- Metric equivalents to imperial gauge.

- What size pilot hole to drill in timber substrates for the best screw grip.

- What size clearance hole to drill through the timber being fixed.

- Which size plastic wall plug to use with each screw size or gauge.

Righty-ho, lets jump right in…. (you can download a free PDF of this table at the bottom)

Gauge |

Metric equiv. |

Pilot hole |

Clearance hole |

Masonry plug size |

| 3 | 2.5mm | 1.0mm | 3.0mm | Yellow (5mm hole) |

| 4 | 3.0mm | 1.5mm | 3.5mm | Yellow (5mm hole) |

| 6 | 3.5mm | 2.0mm | 4.0mm | Red (6mm hole) |

| 8 | 4.0mm | 2.5mm | 4.5mm | Red (6mm hole) or Brown (7mm hole) |

| 10 | 5.0mm | 3.0mm | 5.5mm | Brown (7mm hole) |

| 12 | 5.5mm | 3.5mm | 6.0mm | Brown (7mm hole) |

| 14 | 6.5mm | 4.0mm | 7.0mm | Blue (10mm hole) |

(click to download and print the screws explained table as a PDF to keep for reference)

Pilot holes and clearance holes in more detail…

(I got a few emails about this….. :-))

How tight is tight?

The pilot hole recommendations in the chart are typical for softwoods. Hardwoods may well need a slightly larger pilot hole. If the screw starts to get too tight, then it’s advisable to back out and re-drill a larger pilot hole rather than risk breaking a screw (you’ll be having a very bad day if you snap a screw…..).

In fact, if any screw starts to get very tight, it’s best to stop and have a rethink before you break the screw or burst the material. Screws should be tight, but not crazy, “sweating to get them in” tight! Simply hit reverse and take it out.

Then you’ll need to consider whether to use a smaller gauge screw or drill a larger pilot hole if it’s in wood. In masonry you always have the option to re-drill the hole one size bigger (drilling through the existing wall plug) and use a bigger plug, red up to brown for example.

General Tips

Incidentally, gauge relates to the thickness of a screw’s shank or body and only relates to imperial sized screws. Metric screws are simply measured and the thickness is given in millimeters. The metric screw equivalent size is approximate, but since we’re heading that way, we need to learn and get used to them!

By coincidence, the size of an imperial screw head also roughly equates to the gauge. For example an 8-gauge screw has an 8mm wide head…..handy huh?

How deep does a wall plug need to be? I talked about this a lot on another post, here’s the link: How to Properly Use Wall Plugs

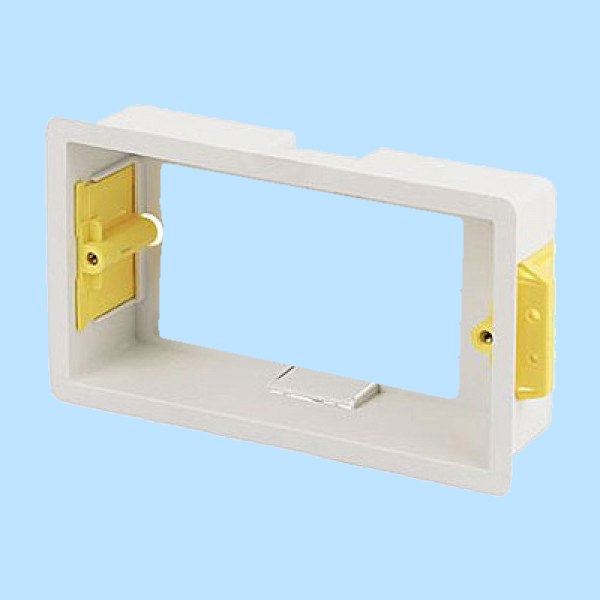

Parting note about wall plugs: Be aware that not everyone follows the colour ‘rules’, one leading brands plugs are all grey for example, and others are, well; they can be any colour under the sun (as the above photo of my box shows). Blue wall plugs are another example, they can be either 8mm or 10mm, go figure! If in doubt always measure the plug at the thicker end to make sure it’s right for the size hole you have drilled.

Hope that helps you sort out your screw dilemmas. Feel free to send this to anyone you know who needs their ‘screws explained’ lol! And don’t forget to let me know how you get on. Incidentally if you want to help support this site, grab your… screws etc. from ebay… Ta muchly!

Stay well

Ian

Comments 96

Hi Ian – Many thanks for this handy table! Numerous Internet searches left me very confused as to which type of wall plug(s) I needed (vague and ambiguous info, unfamiliar terminology, …). Found exactly what I needed on your site and am so impressed have now subscribed to the list (have just moved into my first owned flat – as opposed to a rental – so I’m certain it’ll help me become more “handy” ). Thanks again!

Author

No worries David, glad to be of service 🙂

Cheers for now

Ian

Hi Ian not a diy man bought these https://www.toolstation.com/heavy-duty-tool-holder/p87947 to hold a hedgetrimmer on a masonry wall in cupboard can i screw these directly into wall or would i need rawl plugs if so which size? the screws thread is 10mm length is 40mm

Regards Graeme

Author

Hey Graeme,

Sorry, I missed this question, did you get it sorted or do you still need help?

Ian

Hi Ian,

Thanks so much for your reply, I really appreciate the advice! I am pretty sure the wall is timber with plasterboard as you mentioned above. It’s an internal wall in my bedroom and our bathroom is behind my room – we had this redone recently and I saw the bare bones of the bathroom which also was timber and plasterboard. I’m going to get some of the plugs you recommended and give this a go! Thanks again for your help, your website is really helpful, thanks Sim 🙂

Author

You’re welcome! Hope the little ‘project’ goes well!

The only thing to watch out for is hitting a wooden stud. If you do, just don’t use the plasterboard anchor and just drive the screw into the timber, easy!

Cheers

Ian

Hi Ian, this is really interesting – thanks so much for sharing your wisdom! I’m very new to DIY, and I have a question on putting up a picture ledge that I hope you could help with. I bought a picture ledge from Ikea and it’s already got 2 holes drilled into it – I measured the size of the holes and they’re 6mm. I’d like to hang the ledge on a plasterboard wall, and am finding it tough to figure out what size screws and wall plugs I need – like you said, the information out there is so varied! I’d appreciate any advice you have on what I need to hang this up? Thanks in advance, Sim

Author

Hi Sim,

Thanks for the kind words! It really is all about understanding the wall’s construction. It’s possible you have block walls and plasterboards are ‘stuck’ on to the wall using adhesive. Or it could be timber studwork with plasterboards (common upstairs)?

Generally you’d want the biggest (i.e. fattest) screw which will go through the hole. So, 4 or 5mm in this case. If only in plasterboard I like the hollow wall anchor in this pic…

These come with a screw.

These come with a screw.

Otherwise, if you’re going into masonry (behind the plasterboard) then you’ll need a red (6mm) or brown (7mm) Rawlplug and around 2.5 inch 8 (red plug) or 10 (brown plug) gauge screws (65mm x 5mm metric).

Get back to me if you know more about the wall 🙂

Cheers for now

Ian

Great table, but an additional column listing appropriate masonary bit size would be good.

Author

Hey Ken,

Thanks for the comment. I included the hole size on last column, in brackets…

Best of luck with your projects!

Ian

Hi Ian. I’m one of those people who have to have every single thing explained (!) Am I right that if I drill a 6mm hole into a brick wall, use a red plug and then an 8g screw 2 and a half inches long I have got the right idea?

Author

Hey Mairin,

Sorry for the delay, been working way up in the mountains and not been checking in very often.

Yes, you’re about right 🙂

Just make sure you tap the red plug into the wall a little so that the end of the screw ends up a few mm’s past the end of the red plug, once it’s fully tight.

Good luck!

Thanks so much Ian. Yes I saw you do that with the screw, so that was another mystery clearly explained. 🙂

This is an excellent and useful article on screw fixings. I used it this morning to show new member of the team here at Spur Shelving the difference between different fixing sizes and which plugs to use. I explained how using a substantial fixing on flimsy twin slot uprights will not work as the countersink is not deep enough but on genuine Spur which we make in Devon England will take the larger screw size and still allow the bracket to fit. I guess we got the design right in 1952 so why change it. Insist on the best it will be branded Spur UK.

2 Questions: 1) I have a bunch of plugs (all colors) and a bunch of screws. Now, how do I know which plugs to use with which screws? 2) I need to hang a heavy mirror on a lath and plaster wall. Do I use plugs + screws? Is there a tip on drilling into plaster walls? Many thanks.

Author

So sorry Jan,

Been without internet in Croatia for ages and have been travelling back. Your message fell through the gaps in the internet.

Probably too late now but to answer, I wouldn’t use plugs and screws on lath and plaster unless it’s a very light item.

A heavy mirror really needs to go into the studs of the wall. You can find them with a big magnet or a wall/metal detector etc. to find the nails holding the lath to the studs. Once you have the studs located you can go ahead and use normal wood screws. Use a thick gauge though and drill a pilot hole appx half the screws diameter of the big screw might get stuck half way in.

In a pinch you can use a plasterboard fixing which opens out behind the plaster. Use one designed for double boards, i.e. 20mm+ in thickness.

Let me know if you get stuck and sorry again for the tardy reply.

Ian

I think the chap talking about STAR screws needs to have the difference between Phillips head and Posidrive heads, how to recognise them and which screwdriver to use.

A Phillips screw merely has a cross on the head and a phillips driver is essentially the same – just ensure that your phllips is the correct number.

A Pozi screw has a little whisker market between each quadrant of the cross in the screw head and the driver for it has a cross with a little fillet in each quadrant of the cross

If you put the phillips in a pozi or vice versa you will feel that it does not SEAT firmly/cleanly whereas the correct driver fits the correct screw snugly. Again, like the phillips Pozi has several size numbers

For both phillips and pozi the MAJORITY of average sized screws would use either a PH2 or a PZ2 driver head.

Author

True Erik. Put it this way, I only have space for one permanent screwdriver in my pocket and that’s always going to be a PZ2. Although, it would be closely followed by a T20 star these days. Star drive is increasingly common, but I don’t see the Pozzies disappearing anytime soon.

Thanks for dropping in, hope you found something useful!

Cheers

Ian

Why (M) sizes in machine bolts, equivalent in mms?

Author

Hi Bernard,

I’m not quite understanding your question, sorry! This post talks about wood screws…

Let me know if you have questions…

Ian

what if you are trying to buy a matching screw?

I was trying to buy a substitute for an Ikea fastener, and I just needed a screw that matched the diameter and length so it would bite into the wood at the predrilled hole.

The fastener would twist into a #12 hole on the plastic measuring card at HomeDepot, so that’s what I bought. Is that the gauge of that screw–the shank only?

I ask because The Home Depot guy was dropping the screw into a hole in which the threads would fit, and I thought maybe I was doing it wrong.

Also–should pilot holes be drill a little bit smaller than the shank (for greater pressure), or exactly the same size?

Author

Hiya,

Well, a #12 hole is 4.8mm wide I believe. If the hole you have is 4.8mm (and that is in effect your pilot hole) then you’re going to need a screw the next size up. To be honest, you might be more familiar with sizes in the US (I’m in Europe…)than me! Re the pilot hole, yes you can go a fraction smaller than the shank size in most cases, but in thin particle or chip board I’d be careful. Exact size also works in most cases. It really is a case by case/ trial and error (or experience of course!) because each type of wood and each type of screw behaves differently. A fat screw in a hard wood is different to a skinny screw in a soft wood for example. I wrote this post yesterday actually! click… Metric wood screws explained

Let me have more details or a even a pic two two, and I’ll take a look for you 🙂

Ian

I have 2 inch screws to hang a shelf and was wondering what size of raw plug to use for them any help would be appreciated

Author

Hi John,

Depends on so many things! (sorry).

Assuming the wall is masonry (brick, block etc.), then a red 6mm plug is fine. If the screw is a bit fat, i.e. 10g or 5mm etc. then go up to a brown 7mm plug.

If the wall is plasterboards let me know and I’ll go through that.

Cheers and good luck!

Ian

Would be nice if 7mm glass bit drills were more available at a good price .these are fantastic at drilling accurate holes for masonry I normally use a 6 mm drill and the finish with 7mm cobalt drill for brown plugs for 5mm screws

Author

They certainly leave a very clean and accurately sized hole! For years I used to use a 5.5mm SDS bit for my red 6mm plugs because like you noted, a 6mm SDS bangin’ around in a brick and especially a block leaves a hole slightly oversized. Thanks for stopping by Dave.

Ian

Most helpful. Thank you..

Author

You’re most welcome Mr Morad, hope your project went well?

Thanks for making the time to say thanks, appreciate that 🙂

Ian

Dear Ian, your site is brilliant!

I’ve got a glass writing board to fix and they’ve provided white rawl plugs which say U8 on them. Can you advise whether i just use one drill bit, and which size? I think I don’t need pilot holes etc with the rawl plug.

Thank you!

Judith

Author

Hi Judith!

Best thing to do is measure the diameter of the plug at the top I think. White usually means a generic brand. If it measures around 8mm, then you were right the U8 probably refers to using an 8mm drill bit. And yes, no pilot holes, that’s just if you’re going into wood.

I’m assuming your wall is masonry? If you’re going into drywall etc. then you’ll need some special drywall fixings which spread out behind the drywall (let me know).

Cheers and let me know how you get on.

Ian

Hi Ian, I need to hang a fairly large tv. The bracket I’ve brought is supplied with and has fixing holes that comfortably fit M6 size screws/bolts. I will be fixing into a chimney breast masonry wall, that is subsequently covered by plaster board. However the cavity between the plaster and breast is a depth that requires the M6 bolts to be about 150mm long to achieve a suitable anchor into the brick and protrude to allow a fix on the bracket. I have a good quality stud detector and have established that there are no frame struts suitable to accommodate the requirement. I can purchase the 150mm M6 bolts, but what size drill bit would you use/and what rawl plugs would you use? Many thanks Geoff

Author

Hi Geoff!

Little concerned about the gap Geoff. A 6mm bolt will flex and bend down allowing the bracket to sag, plus you’ll not be able to tighten the bolts up onto just plasterboard. What exactly is the gap? Normally for heavy stuff like a TV bracket you would be looking at creating a solid substrate to screw back onto. How you do that depends on the gap and the materials. Sometimes on ‘dot-and-dab’ walls, this can mean cutting out a square and re-bedding a new piece with a full backing of adhesive. I saw a guy do one once by drilling a few 25mm (1″) holes through the plasterboard, packing in some fibreglass (at the bottom, to stop the adhesive falling down) and then pushing lots of drywall adhesive into the large holes until the area around the holes filled up with adhesive. Once it had set, he remarked out the holes and drilled into the brickwork as normal. The adhesive allowed him to really pull up the bolts and not squash the drywall. But there are lots of other ways…

Let me know the gap and we can talk again (it sounds like there are some timber battens or framing over the bricks to take the plasterboard?).

Cheers

Ian

I’ve have a problem with creating a small hole in a solid brick wall. What would be the smallest you could create? It was for a towel rail and the fittings supplied just seem to be too small. Both have already failed. Do I increase the size of the wall plug? I’d like to use the same holes.

Is there a discussion on the types of ‘star’ screwdriver and matching them with the correct screw. I never know what I have once the are out of the packet. Another topic I guess……..

Author

Hey Mike,

For sure the fitting supplied go straight into the bin in most cases on my jobs! To be fair, the manufacturers don’t know what you’re fixing into and they seem to assume solid concrete!

In brick though, the plug size isn’t critical. I’d go for a 6mm red plug and an 8g screw at least 2 and a half inches long. You could go even bigger and go for 7mm brown plugs and a 10g screw of the same length. These are the two most common sized plugs used in the UK.

The absolute key factor is getting deep enough into the brick for the plug to do its job. If the plug is flush with the surface of the plaster, it’s going to pull out. Read up a little more here…

Re the star drive, I’m not sure what you’re asking! Get in touch and I’ll help if I can.

Cheers

Ian

Hi Ian, I have 10x50mm coach screws. What rawl plug size should I use? And What drill bit size? I will hang a large mirror on a concrete wall. Many thanks.

This is the picture of the screw I bought. Its on their website. Many Thanks!

http://www.screwfix.com/p/coach-screws-10-x-50mm-10-pack/64576

Author

Hey Ven,

Thanks for getting in touch. Hmm, a coach screw is really designed to go into wood. Unless you buy them as a ‘kit’ (like a basin hanging set) I think you’re going to struggle to find a wall plug big enough to use on a M10 bolt. Just how big is that mirror lol!

Usually I would use a heavy gauge regular (12g/14g x 75mm etc) screws with a large ‘penny washer’. Make sure the wire goes behind the washer and you’re good to go. If it’s a massive mirror (I’ve hung some more than 3m tall etc.) then I’d use multiple hanging points, they hang better and move less too. Or you can use a hook of some kind… http://www.screwfix.com/p/smith-locke-long-robe-hook-brushed-stainless-steel-64mm/8364p or similar. If it’s really, really massive then you should look at rawlbolts (M6 or M8) as a solution.

You mention the wall is concrete, just concrete? In a high rise? Any plaster?

Let me know.

Cheers

Ian

Hi, Ian,

Wow! That was a quick reply. Thank you! You’re the man!

I am a little bit exaggerated when I bought the big coach screws for my mirror, I am just scared that the mirror will fall off from the wall if I use small screws, lol. The mirror will be hanged in the dining here at home, with a measurements of 72” x 36” inches and according on the box the mirror weigh 35kg. Not really that heavy and big for the coach screws I bought,lol. There are 2 fixtures for hanging at the back of the mirror. The hook you’ve suggested will not fit for that type of fixtures attached on the mirror.

I am not really sure if the wall is pure solid concrete, most probably bricks under and cement plaster on the surface. The staff at ScrewFix cannot give me any suggestions, they only sell products (-; Since the mirror is not really that heavy, will you give me any suggestions on what size and type of screws should I use? And also what rawl plugs size and drill bit size should I also use? Many Thanks!

Cheers!

Ven

Author

Hi Ven, sorry to be a bit slower this time! Been in Sweden all weekend and just got home. For your mirror I’d use brown 7mm diameter wall plugs and then a thick gauge screw, a 5.5mm or 12g in old money. Length depends on the thickness of any plaster. 75mm or 3″ should be OK. I’m firing this off quick so let me know if I missed anything… Cheers Ian

Author

p.s. incidentally, I think you should send me a picture of the hanging points, then I can better advise you. 🙂

Hi Ian We’ve just fitted new doors and lever on rose handles. Unfortunately the joiner decided not to use the screws supplied – don’t know why! (He didn’t use the through bolts either but that’s another story) The result is the diameter of the head is slightly too wide for the countersink in the handle and the covering rose plate doesn’t screw fully home.

I have spoken to the handle manufacturer and they don’t supply screws by themselves – why not?? They could only tell me that the head diameter is 4mm and the length is 20mm. I can’t equate this to your table above.

I’ve spoken to several screw suppliers and they all want to sell me what they have in store but no-one has yet convinced me that what I’ll get will have a 4mm diameter head! I hope you can help.

Author

Hi Brian,

Highly likely it will be an engineering type, i.e. one from a range of special screws not readily available to us. The table I put together is just for regular wood screws.

Hmm, you say you just need to get the cover plate back? Would grinding a little off the top of the screw work do you think? It might leave the drive a little small for the screwdriver though… Alternatively, can you increase the countersink a little (without going all the way through!)?

A picture might help me…. 🙂

Let me know if I can help.

Ian

p.s. I think it is disgusting the handle manufacturer was unwilling to help, that sort of thing appalls me.

p.p.s. a 4mm head is approximately a 4g screw though…

Hi Ian,

I’m looking for a bit of help.

I’m mounting a TV to my wall and the bracket has come with 10.5mm plugs and the corresponding screws but no note of what size masonry bit I’ll need to make a hole to accommodate. Is it as simple as a 10.5mm bit?

It’s going on a plastered brick wall.

Thanks, Chris.

Author

Hi Chris,

Pretty hefty plugs! I’m 99.9% sure it will be a 10mm hole. The plug may measure a little more but it will compress slightly when it’s pushed/hammered into the wall. What length are the screws/plugs? Just that sometimes it’s best to sink the plugs into the wall a little (if the screws are long enough). Ideally you want the bottom of the screw and the bottom of the plug in the same place. i.e. if you’ve got a 50mm long plugs and 75mm long screws you want to push the plug into the wall 20mm or so. Especially as the plaster has little holding strength when hanging heavy items.

Let me know if you get stuck!

Cheers

Ian

p.s. you might find this useful….. handycrowd.com/quick-tip-using-wall-plugs-rawlplugs-in-a-plastered-wall

Great information – I live in Metric land so getting a cross reference to the ‘old’ standard is always useful.

I don’t use wall plugs, you never seem to have the right size. Instead I use chopsticks! The chopsticks in the take-out are usually made of softwood. I simply bang a chopstick into the drilled hole as far as it will go, then break it off and in with the screw.

Where I live in Indochina we can only get hardwood chopsticks. They can be used in the same manner only before you make with the screw and screwdriver, I crack the wood by banging a flat-blade screwdriver in to the wood to crack it so the screw has a pilot hole.

Author

Great tip Jay! I’ve also done something similar using matchsticks or cocktail sticks, just fill up the hole with them and snap them off flush with the surface. Job done! Happy New Year to you 🙂

Hi Ian,

I need to mount a handrail on top of a low (18 inches high) brick wall which is topped with hard (but not architectural)bricks laid on edge, i.e. like “soldiers” laid flat on their backs (rowlocks?) The base of each handrail post is a 100mm diameter steel plate with 4 x 5mm holes in each, the hand rail post is 50 cm tall so will exert an amount of leverage if leaned on.

My question is what is the best fixing option? 1.5″ rawplugs with 5mm screws doesn’t sound deep enough? Does anyone make brown rawlpugs 3 inches long? 8mm anchor bolts could split the bricks? I guess I could (resin) glue in steel threaded rod and fix down with nuts? And I’m guessing at least a proportion of the holes will be forced to end up in mortar rather than brick.

Any suggestion welcome!

Thanks, Andy

Author

Hi Andy,

Yes, the leverage could be considerable. Especially if someone falls or pulls on it etc. I’m assuming it’s outside so whatever you choose obviously needs to be suitable for prolonged outdoor use.

My only comment would be to get the fasteners as deep into the wall as you can practically go, preferably below the top course. Don’t worry about the length of the brown plugs, just tap them deep into the hole until there is only 40mm (or equal to the length of the plug) of the screw/ bolt sticking out. Then the holding point is down at the bottom of the hole. Longer plugs are available but these are ‘frame fixings’ and not designed to be used outdoors.

Resin is obviously a great way forward as it holds well without creating stress, but it’s much more work and the nuts don’t look as neat as a screw or bolt head.

I think with it being ‘only’ 500mm high, I’d be tempted to get long outdoor screws, preferably with a hex head and then use regular wall plugs as deep as I could get into the masonry. Drill holes very slowly and carefully (SDS etc)and blow out the dust (seems worse on vertical holes as the bit doesn’t clear as well as horizontal holes). Don’t worry too much about hitting mortar, obviously if it’s three out of four holes maybe! As long as it’s only the odd one, it should still hold well. Any really bad holes you could resin fill maybe and push the screw into it (seen this done with outdoor ‘no-nails’ type stuff in a pinch, he left the screw a couple of turns proud and nipped it up after 24hrs… big dodgy but what can you do sometimes!).

See what they have at the store screw/length wise, stainless steel is best of course. You could even consider structural timber screws, if you can get a wall plug big enough for them. They are long, have flanged heads and designed for outdoor use, just a thought (Have a look at what I mean at screwfix…).

Let me know how you get on!

Thanks for calling in

Ian

Author

Hi Andy,

Yes, the leverage could be considerable. Especially if someone falls or pulls on it etc. I’m assuming it’s outside so whatever you choose obviously needs to be suitable for prolonged outdoor use.

My only comment would be to get the fasteners as deep into the wall as you can practically go, preferably below the top course if you say they are laid flat. Don’t worry about the length of the brown plugs, just tap them deep into the hole until there is only 40mm (or equal to the length of the plug) of the screw/ bolt sticking out. Then the holding point is down at the bottom of the hole. Longer plugs are available but these are ‘frame fixings’ and not designed to be used outdoors.

Resin is obviously a great way forward as it holds well without creating stress, but it’s much more work and the nuts don’t look as neat as a screw or bolt head. I agree that metal expanding bolts could be too much for the brickwork in this case.

I think with it being ‘only’ 500mm high, I’d be tempted to get long outdoor screws, preferably with a hex head and then use regular wall plugs as deep as I could get into the masonry. Drill holes very slowly and carefully (SDS etc)and blow out the dust (seems worse on vertical holes as the bit doesn’t clear as well as horizontal holes). Don’t worry too much about hitting mortar, obviously if it’s three out of four holes maybe! As long as it’s only the odd one, it should still hold well. Any really bad holes you could resin fill maybe and push the screw into it (seen this done with outdoor ‘no-nails’ type stuff in a pinch, he left the screw a couple of turns proud and nipped it up after 24hrs… big dodgy but what can you do sometimes!).

See what they have at the store screw/length wise, stainless steel is best of course. You could even consider structural timber screws, if you can get a wall plug big enough for them. They are long, have flanged heads and designed for outdoor use, just a thought (Have a look at what I mean at screwfix…).

Let me know how you get on!

Thanks for calling in

Ian

Hi Ian

Thanks for a very informative article.

My question is what plan can I make to secure a plug cover to a wall electrical plug box on a wall where some plastering work has caused the depth of the plug box to be beyond the standard M4 100mm length? At the moment I’m not sure exactly what length M4 will reach the wall box bracket, but it will probably end up being in the region of 120 to 140mm.

Someone suggested that I cut the head of a M4 40mm and then use an electrical ferrule and connect the headless M4 40mm to a M4 100mm by crimping the two screws together inside a ferrule. Do you think this “cowboy” type plan might work? Or do you perhaps have any other suggestions? Any advice or input will be highly appreciated.

Regards,

Alex

Author

Hi Alex,

Well, what you suggested would of course work, but a better way would be to extend the box forward. You can actually buy ‘socket box extensions’, but my experience finds that not many places keep them in stock. However, I have a cunning plan……

You can make your own (no, not with a cornflake box and sticky tape) but rather you can ‘convert’ a regular back box, preferably a deeper one like this… from Screwfix or such like.

from Screwfix or such like.

Then what you do is drill two holes in the back of the box corresponding to the holes on the front. Then using a mini grinder fitted with a 1mm cutting disk, carefully cut out the majority of the back of the box, making sure you leave the part with the holes you just drilled. I leave about 5mm on the top and bottom too for added rigidity.

Like this…

Then you simply screw this box on top of the existing back box and lo, your new screw fixing points are 50mm further forward (or more or less depending on the box you chose. You can even do this multiple times (you can buy 25, 35, and 50mm boxes or more).

What I like about this method is that it stops the electricals being ‘in the wall’, stuff sparks like heck when you plug them in and out and I hate to think of that being in a open space with access to flammable dust etc. I live in Norway now and here they still use a fully contained system of plastic tube and back boxes, brilliant for making mods in the future and it protects the (mostly wooden) houses from such sparks. We used to do the same in the UK with metal ‘knob and tube’ up until the 1950’s or thereabouts.

Hope that gives you an alternative and I really must write up this tip into an article (so thanks for that push!)

Let me know how you get on.

Cheers

Ian

p.s. if you’re worried out the sharp edges of the cut out area, it’s easy to shield them by making a ‘grommet’ out of some thin plastic tubing cut on one side. I have access to lots of ‘hospital drip’ tubing (wifes a nurse you see) which is about 3 or 4mm tube, perfect when cut down one side with some tiny scissors (also ‘single use’ from the hospital lol!).

p.p.s. You don’t say what the plasterworks are, but if it’s dry lining in front of the socket and the plaster is going to be plasterboard why not cut out the back of a plastic ‘drywall’ box and fit that into a new opening in the plasterboard and not use the old backbox screws at all? Like this…

p.p.p.s…… nope, that’s all 🙂

Hi Ian, thanks a lot for the knowledge share!

I have a slotted square 80mm hook which I want to use for hanging a large mirror on a masonry wall. I am looking for an appropriate wall plug and the closest I have found is a 70mm at Screwfix. Will that work ? Thanks.

Author

Hiya,

It depends more on the diameter or gauge of the screws shank really. You might find that a large plug like a 70mm one is designed for a really large diameter screw (5 or 6mm plus).

Difficult without knowing the weight of the mirror, but I’d have through that an 80mm slotted, square hook would be fine with a regular brown 7mm plug, making sure that you push the plug into the masonry itself and through the plasterworks.

Any mirror that needs more than this should be hung on a pair of hooks in my opinion (gives better leveling too).

Don’t forget that the weight is mostly in ‘shear’ too; i.e. it’s trying to pull down on the fixing and not too much force is trying to pull the thing out of the wall!

Another point is that heavy loads are as much about the substrate as the actual fixing. Old crumbly masonry (for example) or hitting a largely empty (of mortar) cross joint in blockwork (for example), will cause more problems with failure than screw size itself.

Let me know more details (mirror size/weight/ hook shank size etc.) if you need more specific help. We have hung really large mirrors (like six feet tall heavy/ gilded things) on pairs of thick shanked screws in brown plugs with no problems.

Thanks for the kind words,

Cheers

Ian

Hi Ian, very useful article thank you.

I have 10mm lag screws that I need to fit into a 15mm render and 100mm concrete block wall. Shank is 30mm and screw thread is 50mm. Can you advise on suitable plug toninsert to a depth of 80mm Thank you.

Author

Hi Rob,

Can I first ask what you are fastening to the wall? It’s just that plastic wall plugs of the size you’d need for a screw that size are not in common use. Sure you can buy ‘sets’ of big screws that come with a large plastic plug (sink/washbasin screws to name one) but usually if you’re hanging something heavy on a masonry wall you’d use a ‘rawlbolt’ style expanding bolt; either a hex head and washer or a nut and washer.

However it’s just occurred to me…. by 10mm lag screw, do you mean a screw with a 10mm head? Then the screw shank will obviously be much smaller. I used to use a lot of 10mm hex headed screws to fasten thin metal profiles to brickwork and these went into a 10mm hole with a blue 10m wall plug. Otherwise it’s best to head into the store and find the biggest plug that will take the screw shank diameter (the threaded part but minus the actual threads).

Well, I think I’ve suitably confused matters 🙂

Let me know what you’re fixing up and clarify the shank diameter of the screw and I’ll be much more specific, I promise!

Best regards

Ian

Hi, I know this is an old post, but I still hope that you can help. I am hanging a TV bracket. 8mm holes, 8mm plugs. What size screw do I need? Around 6mm? ty in advance

Author

Hi Sadie, a 6mm might be OK, but they might get a little tight going into an 8mm plug. I would start with a 12g or 5.5mm to be honest. It’s difficult to be exact as it really does depend on the plug and the cleanness of the hole drilled etc.

Let me know how you get on.

Ian

Hi Ian, Thank you so much for the comprehensive guide. This is by far the most useful information I have found on this topic.

There’s just one point which I’m struggling to understand. You say at the end of the article:

“By coincidence, the size of an imperial screw head also roughly equates to the gauge. For example an 8-gauge screw has an 8mm wide head”

However, when I look at the table, an 8-guage screw is ~4mm in diameter. So, am I right in assuming that the statement above only refers to the screw head not the thread?

Author

Yes Ahmed, just the head. The thread is as stated in the table. Thanks for the thanks! Ian

Please help me. Am i meant to measuring the threaded part of the screw or the non threaded (shank only) of the screw? A Number 10 Screw seems to have a 5.0mm thread but a 3.5mm shank? To confirm we are talking thread only yes?

Author

Depends what you are drilling. Pilot hole; then measure the shank. Clearance hole; measure the outer diameter of the threads.

Hope that clarifies!

Ian

Tried to find some info about screws, read a bit and then your picture jumps up on my screen – glad you got top spot on google, and thanks for the info. Hils fra Snarøya

Author

That’s why the millions are rolling in lol! What’re you making? Something scary for Halloween I hope 🙂

I’m home alone this year….gulp!

See you soon,

Ian

Hi Ian

I have a large box of mixed screws which I would like to sort into size order. I would like a plastic gauge so I can simply poke the screws through the holes to determine their size. Can’t seem to find one on-line, only US.

Any assistance will be appreciated.

Helen

Author

You’re right, I don’t think any such gauge exists here. Well, I had an apprentice once who was a bit of an ‘eejit’ and used to drop screw boxes on a regular basis!

To get them sorted out we grabbed a piece of cardboard and taped each screw size to it, to help him visually judge what size screw he had picked up.

However this method does require that someone knows what size each screw is to start with so that you can make up the guide board!

If you have some boxes of screws you can use them to help you learn the thickness of each gauge of screw, then it’s a simple matter of sorting out the length with most folks can do pretty accurately with practice.

Sorry there is no silver bullet Helen! But if you crack the gauges by experience, the lengths are easier…..

Thanks for reaching out,

Ian

Thanks Ian. Please keep me in the back of your mind in case something turns up. I don’t have any boxes to match up against and, if I buy any it rather defeats the object!

Author

Are they all the same type of screw Helen? (maybe take a picture of the box and let me have it….) Just that a ‘normal’ wood screw with an 8mm wide head is an 8 gauge screw. Unfortunately it’s the only one that is so convenient, but I could measure the heads of the different sizes of screws and that would give you somewhere to start.

Also, there is only a few main ones. Most folks in the trade use 8’s and 10’s for most stuff. Small screws might be 6 and very small 4’s. Big screws above 3″ can be 12’s or even 14’s.

🙂

Ian

Just a thought … I’ve got a set of drill bits in a nice plastic box. The holes for the drill bits are all labelled (metric: mm). Tip all the drills out and bingo – a nice template for measuring screw sizes, at least in mm. I assume the notional screw size is the same as the smallest hole it will fit in?

Course, then you’ve got to sort the drill bits to put them back in the box 🙂

Author

*laughing* I do this all the time! Especially when drilling clearance holes for screws, bolts etc. Simply take out the drill bit you estimate is big enough and then slide the screw/bolt into its hole and there you are, instant gauge (but don’t try this for pilot holes, they’ll end up too big!).

Nice one Robin, I’ll add it to the article when I get a mo.

Cheers

Ian

Hi Ian,

I would like to know what wall plug size (blue or brown) should I use for a 8mm hole? Thank you!

Author

Hi Lal,

Definitely not a brown plug as they are 7mm and blue plugs are usually 10mm so neither are any use in an 8mm hole. However some stores will stock 8mm plugs. Fischer used to make an 8mm plug I believe (all their plugs are grey.) Or alternatively you could drill the hole one size up and use the blue plugs.

I’d check the store first for an 8mm plug though, try here….. 8mm plugs from Fischer

Good hunting!

Ian

Hi

I have got a piano hinge to attach to mdf 5mm thick. I need brass wood screws 5mm head x 5mm length (max) but cannot find anywhere to buy them. Can you help

Thanks Bob

Author

I don’t think you will Bob. Maybe in the States but I’ve never seen anything that small in local stores/merchants in the UK/etc. You could try a specialist machine screw place but it’s likely the threads will be too small to hold in MDF.

Have you considered bonding the hinge in place? Then you could use a longer screw (cut short) into VERY carefully drilled pilot holes to fill in the hinge holes and look ‘proper’.

Depends on how big the lid is I guess, but I will tell you that MDF doesn’t hold a screw that well, even in thicker boards and in 5mm stuff it’ll be very poor indeed.

Feel free to let me have more details on the job!

Thanks for looking in Bob,

Cheers

Ian

Hi Ian

Daft question I guess, I have screws/bolts size 2 and a half inch in length heads about 8mm and bout width is 6 mm it’s to re hang tv bracket can you give me any advise.. I am lost on what size plugs to buy. Kind regards Paul

Author

Hi Paul,

You might get them in a 7mm plug but 8mm would be better (if you can find them). Just wondering, did they come with the bracket? To be sure, put one over a tape measure and take a pic and send it to me and I’ll know for sure. It depends if the 6mm is the shank width or the thread width.

Cheers

Ian

Hi. Thanks for all the size info, but what type of screw is needed? A basic wood screw?

Author

The table pretty much covers all types of screws (since it mostly covers thickness and length) so what screw you choose depends what you’re fixing. But generally, standard wood screws are used for most things and coated screws for anything outside. Brass or stainless steel is common for more decorative stuff on hinges or handles etc.

If you want I’d be happy to help if you let me know what you are doing and what you’re fixing to etc.

Cheers

Ian

Thank you, thank you, thank you for your ‘plain English’ explanations. Makes life so much easier for a DIYer.

Author

You’re most welcome Janice, glad it helped 🙂

Best presented practical data on screws that I have seen. Very useful, thanks.

Author

Thanks Richard, these things are often over complicated aren’t they?

It is my pet hate when a manufacturer says 6mm to 9mm (random example) in their installation specs, OK, I get that there is a range, but since I am stood here with a tape and can make it what ever I want, I want the optimum size!

Thanks for the nice comment!

Cheers

Ian

Ian, is there a ‘permanent’ code for the relationship between the drill bit mm size, rawl plug size and the actual screw size to use? Plus, – how is a screw size, say, 8mm, what is that?

Author

Hi Danny,

There is a strict relationship between the drill size and the rawl plug size with zero adjustment. A brown 7mm plug needs a 7mm hole for example. However the size or gauge of screw the plug takes is flexible, according to the manufacturers. A brown plug might take anything from 8 to 12 gauge screws (4mm, 5mm, 5.5mm) for example.

As for the 8mm screw you mention, well it depends whether you’re looking at the gauge (thickness or diameter of the screw shank) or the length. An 8mm thickness is more likely to be a type of coach screw or possibly a frame fixing, whereas a 8mm long screw is tiny.

Hope that helps, let me know if you need anything clarifying!

Cheers

Ian

Thanks for explaining this – You’re so right about the colour-guide being inconsistent. Wanting to try drilling into masonry (indoors) & bit wary but willing to give it a try.

Author

Thanks Ophelis. Just go real slow to start with and clear out the dust afterwards and you’ll be fine. Folks that go at the wall like a crazy guy end up with oversize holes and trouble.

Let me know if you need any specific help!

Thanks for stopping by,

Merry Christmas!

Ian

Hi, I am about to install a sky dish for my son? I am useing 10mm bolt for external brick. What size drill bit would you recommend and also what colour wall plug?

Author

Hi Rich,

Depends what you mean by 10mm! Is that the size of the head of the bolt (spanner size) or the diameter of the bolt itself?

Usually most bolts are too big for the ‘standard’ or common brown 7mm plugs. Dishes we’ve done in the past used a blue plug in a 10mm hole (if it’s the 50mm or so, bolts I have in mind)

Take the bolts with you to the store and check the diameter of the bolt’s shaft to the inside diameter of the plug. It shouldn’t be too tight a fit at the neck of the plug, as it will get tight once you get further in.

Let me know if I can be of any further help!

Good luck

Ian

Hi Ian,

I was just wanting to re-check the recommended pilot drill size for No 12 screws (a gate hinge job) and yours was the first page that came up.

(That’s also good advice to stop and re-drill if you think it’s too tight.)

One thought – by the time a heavyweight job needs a No 10 and certainly a No12 screw into masonry, then I’ve almost certainly gone over to a coach screw, or you just can’t get the leverage required to put them in.

6mm – I’d go for a 10mm plug (near enough as above for a No14);

8mm – I’d go for a 12mm plug.

I’ve just used 8mm coach screws in preference to a 10mm self-tapping brick screw for a gate-post on a wall. (I tried one and it pulled the brick facing off).

Rgds

Chris Unsworth

(Competent DiY’er)

Author

Hi Chris,

Thanks for your input, always good to hear others experiences as it adds to my own! Especially when it makes me go back and look at stuff I wrote a while ago, keeps it fresh. I think I might amend the table and add a couple more lines, but like you said it’s getting dangerously close to bolt territory then!

I definitely agree with you re the larger screws, I’ve got nothing over a 10g x 100mm in my box for sure. Bolts or frame fixings for me at and above that. I don’t have too much problem getting the bigger gauges in, as I use a pretty powerful drill driver, but yes, you can’t stop and they need lots of ‘feed’ or you’ll get into trouble. You’d struggle getting them in by hand I do agree.

Also agree with the self tapping stuff. I have been successful with them in dense blockwork when T’ing off with a timber stud wall etc. but somehow I just don’t trust them. Getting too old for new tricks maybe?

Thanks again for stopping by and adding some useful experience Chris,

Good luck with your jobs!

Cheers

Ian

Fantastic bit of info, very concise and easy to reference. Thanks

Author

You’re welcome, glad it helped!

Cheers

Ian

Do you think a hole drilled with a 5mm bit would be too tight for a 4x40mm screw in a red rawlplug?

Author

Hi Stenny,

You’re going to struggle to get a red rawlpug into a 5mm hole, although we used to get them into 5,5mm holes when using small gauge screws. What is the job and your thinking behind drilling a 5mm hole (instead of a 6mm)?

Thanks for calling in,

Ian

Just what I was looking for. Cuts through all the ‘blah’ on other sites.

Thanks

Author

Thanks Grant, glad it helped. Don’t forget to ‘share’ it 🙂

Ian

Brilliant! No nonsense, concise information and table for all you need to know when using screws, drills and plugs.

Author

Thanks Greg! Glad it helped.

Ian